LC MAXI 1275

Rope lift without machine room to a limited space

LC Maxi 1275 is a new type of of the lift without machine room, it has completely replaced the original LC OneSpace 1250.

-

The LC Maxi 1275 can now fit into a shaft with dimensions of 1950x2860 mm.

-

This lift requires a minimum headroom of only 3000 mm and a pit depth of 950 mm.

-

It is a special type of traction lift without a machine room, providing a unique solution for small pit depth and headroom.

-

The space-saving design places the machine in the head of the shaft.

Technical specifications of the LC Maxi 1275

-

Load capacity: 1275 kg

-

Number of persons: 17

-

Maximum number of stations: 10

-

Maximum travel height: 25m*

-

Cabin dimensions: 1200x2300 mm

-

Shaft dimensions: 1950x2860 mm

-

Shaft headroom: 3715 mm (minimum 3000 mm)

-

Pit depth: 1050 mm (minimum 950 mm)

|

|

*In case of a higher travel, please contact our sales department for more information.

Lift characteristics

|

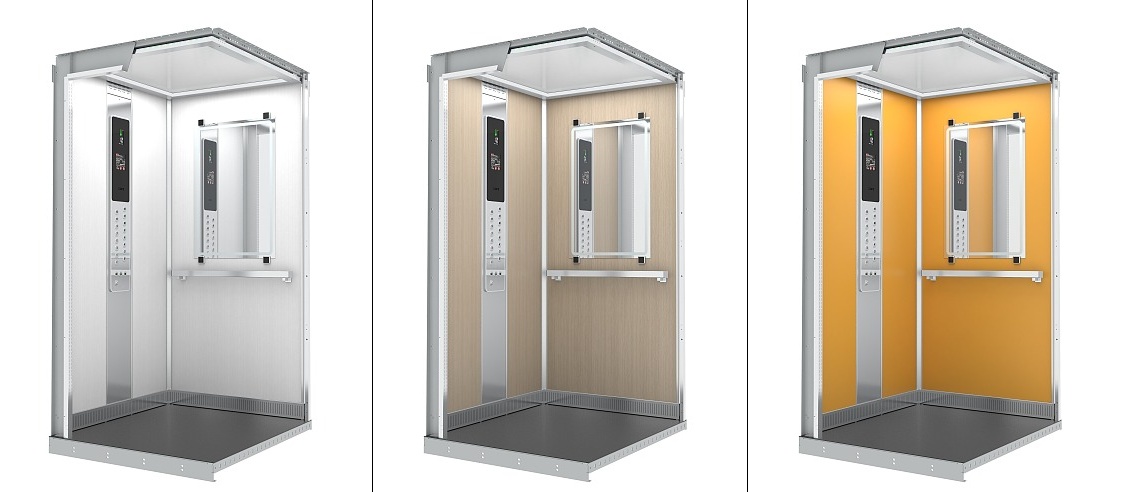

Design cabins

-

Five rows of lift cabins

-

Dozens of lights, accessories, and hundreds of color combinations

-

Crystal-clear surfaces, precise lines, excellent manufactory.

-

Premium materials, stainless steel surfaces, LED lighting, design elements, and frosted glass

-

The cabins are double-sided galvanized, significantly increasing their lifespan.

|

Safe lift

-

All lift components are pre-tested in our testing tower

-

We are an lift manufacturer - a stable company with 100% Czech capital

-

We monitor lifts for your safety - the lift can be monitored from anywhere, anytime, and some issues can be resolved remotely

-

Lifts are equipped with in-cabin communication for emergency situations

-

In case of a power outage, there is an emergency descent feature.

|

|

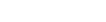

Top-quality components

-

We manufacture lifts for you in our factory in Karviná.

-

We complement our in-house production with high-quality components from leading European manufacturers.

-

Ziehl-Abegg and SICOR machines - our long-standing partners, one of the largest and best machine manufacturers in Europe.

-

-

Steel ropes last up to twice as long as belts.

-

Button panels are installed in the cabin and at the landing station.

|

Swiss manufacturing technology

-

We use excellent machines from Switzerland for production (Bystronic laser and bending presses, Trumpf sheet punching from Germany).

-

LC lifts are manufactured as compatible building blocks using these technologies, ensuring their long lifespan.

-

The construction is lightweight thanks to the utilized manufacturing technology and materials.

-

Main lift components (cabin, frame, brackets, and others) are galvanized.

-

"If components are not galvanized, they often look like they've aged ten years within a year."

|

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

(1).JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)