About us

We are lift experts.

LC Lifts (LIFT COMPONENTS s.r.o.) is a Czech manufacturer of lifts and platforms with over 20 years of experience. We not only produce lifts, but also design, develop, and test them in-house.

Discover what makes our lifts truly different.

10 Reasons to choose LC Lifts (LIFT COMPONENTS s.r.o.)

Choosing a lift based solely on price or glossy catalogs that promise the sky is often a superhuman task. Catalogs are created by advertising agencies, and anything can be promised in text.

How can you tell if the company offering lifts is a true manufacturer, rather than just an assembler of the cheapest components from questionable sources? We often get this question from our customers, and we will try to answer it in 10 key points.

Choosing a lift is a long-term investment. With LC Lifts you get genuine European quality, modern design and technology you can rely on for decades.

1. We are a Czech manufacturer of lifts with 20 years of experience

-

We are a stable and reliable company – producing elevators in the Czech Republic for over 20 years.

-

We are 100% Czech-owned, funding all investments from our own resources.

-

All our lifts are fully manufactured and tested in our production facility in Karviná.

-

We have been awarded AAA Platinum Excellent Stability Certificate, recognizing our company as one of the most economically stable in the Czech Republic.

2. Safety

-

All lift components are pre-tested in our test tower, ensuring the highest level of safety.

-

We continuously monitor our lifts for your safety – you can track your lift from anywhere, at any time, and some issues can even be resolved remotely.

-

Every lift is equipped with voice communication in the cabin, providing immediate connection to our service team in case of emergency.

-

In the event of a power outage, an emergency exit system allows passengers to evacuate safely and quickly.

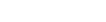

3. We are always close to you - wide business network

-

We are available in every region of the Czech Republic and Slovakia.

-

Our partners are fully authorized and trained.

-

We collaborate closely with our partners on installation and ongoing maintenance.

-

Reliable and affordable service is available in all regions.

4. Swiss manufacturing technology

-

We use top-quality CNC machines from Switzerland and Germany (laser cutting machine Bystronic, press brakes, and sheet metal punching machines Trumpf)

-

Thanks to advanced technologies, LC lifts are built as a fully compatible modular system, which ensures long service life.

-

The main lift components — cabin, frame, brackets, and more — are galvanized, significantly extending their durability.

-

Without galvanization, components can appear worn and aged after just one year of use.

5.Stunning design

-

We offer five series of lift cabins featuring modern designs, dozens of lighting options, a wide range of accessories, and hundreds of color combinations.

-

All cabins are galvanized on both sides, significantly extending their service life.

-

With crystal-clear surfaces, precise lines, and flawless craftsmanship, our cabins combine timeless elegance with modern aesthetics.

-

We use premium materials, including stainless steel finishes, LED lighting, cut glass, and carefully designed decorative elements.

.JPG)

6. Saving energy and the environment

-

Our lifts are designed for low power consumption.

-

The economy mode includes not only the switchboard but also the inverter, displays, and door operator.

-

Up to 90% of the energy used to manufacture your lift comes from solar power.

-

All cabins are equipped with LED lighting as standard.

7. Hi-Tech components

- Our lifts are manufactured using state-of-the-art technology, complemented by proven components from leading European manufacturers.

- Lift engines by Sicor, Cegi or Ziehl Abegg – one of the largest and most respected lift machine manufacturers in Europe.

- Lift doors by Klefer – part of the multinational group Tecnolama.

- Hydraulic engines by Moris and frequency converters from Yaskawa (Germany).

- We never use components from questionable sources.

8. Thorough Testing and Development

-

All our lifts undergo rigorous testing to meet the highest standards of safety, quality, and reliability.

-

We develop and test our lifts in the test tower at our headquarters in Karviná.

-

During testing, we pay special attention to permitted noise levels in protected areas.

-

Lift development is crucial — it is not enough to simply purchase and assemble a lift at the customer site.

9. Lifetime and warranty

- The standard warranty is 36 months, with an option to extend it to 60 months for all major components.

- Advanced engineering and rigorous testing mean that our lifts maintain performance and safety over many years.

-

Spare parts for your lift will be available for at least 10 years.

-

The cheapest lifts, made with components from questionable sources, often result in higher failure rates, shorter lifespans, and spare parts that are nearly impossible to obtain later on!

10. Always something extra

- With LC Individuals, your lift cabin can be fully customized.

- For example, with LC ColorGlass, a unique system of all-glass panels with laminated digital printing, you can perfectly match the entire cabin interior to your personal style.

- LC ColorGlass offers unlimited color possibilities and design freedom that traditional cabin tiling cannot provide.

- You can incorporate graphic elements, artwork, or even your own photos beneath the glass, creating a cabin that harmonizes perfectly with your home’s interior.

Do not hesitate to contact us.

You are welcomed in our showroom.

Take a look at our presentation video

.jpg)

.jpg)

.jpg)