LC Maxi NG (New Generation) - Lift without a machine room

Dear customers and lift enthusiasts,

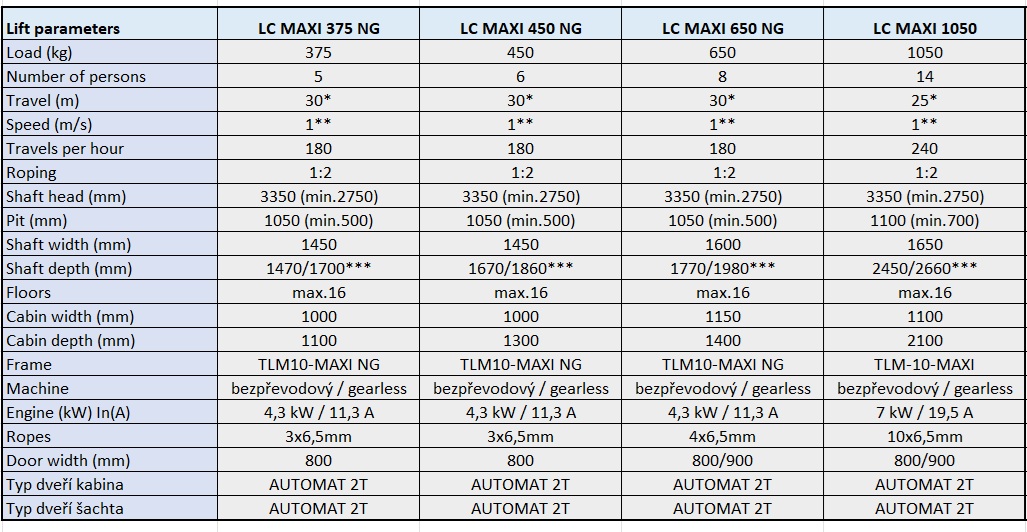

We are pleased to introduce the new machine-room-less lift LC Maxi NG (New Generation), which fully replaces the previous LC Maxi model for load capacities from 350 to 650 kg.

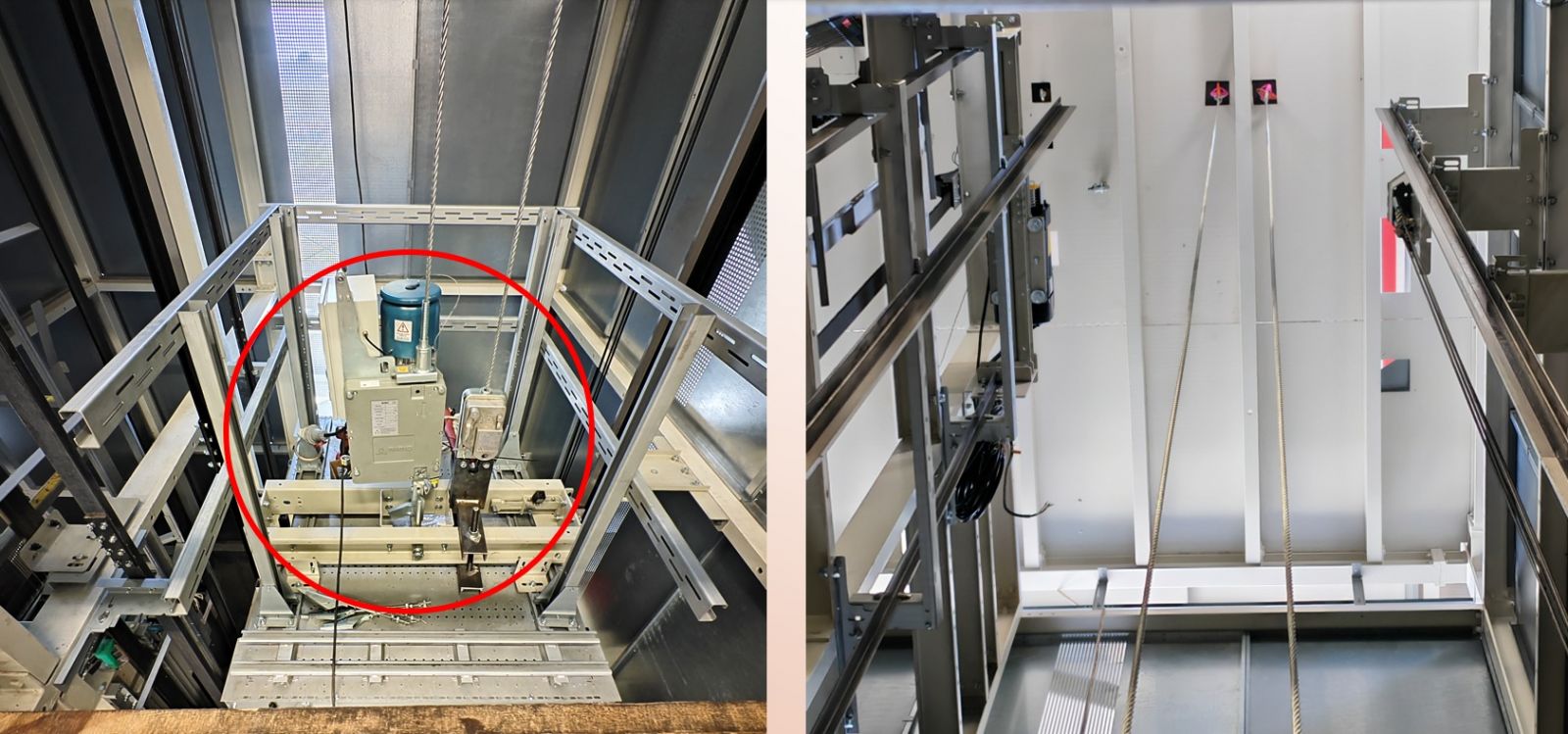

The LC Maxi NG is currently installed in our test tower, where you can experience its excellent ride performance — made possible by the absolute position sensing system.

Read on to discover the main advantages of this innovative product.

Below, you will also find a table with all technical parameters.

Advantages of LC Maxi NG:

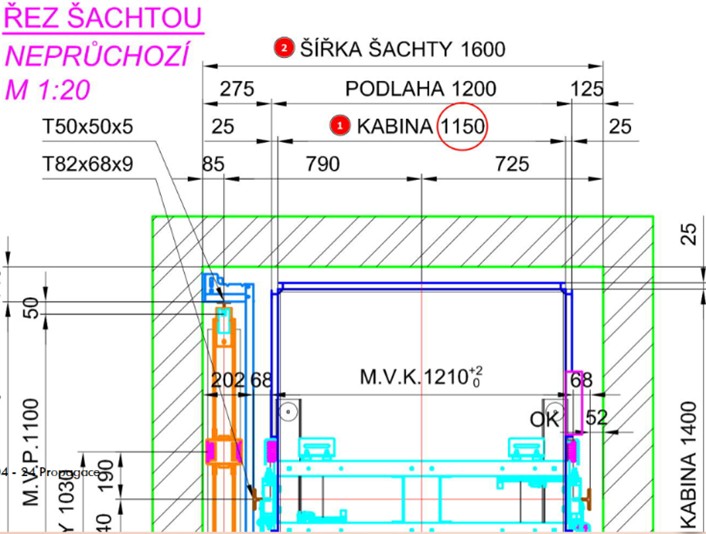

1, Cabin width increased by 50 mm to 1150 mm – while maintaining the same shaft dimensions of 1600 × 1770 mm (for LC Maxi 650 NG)

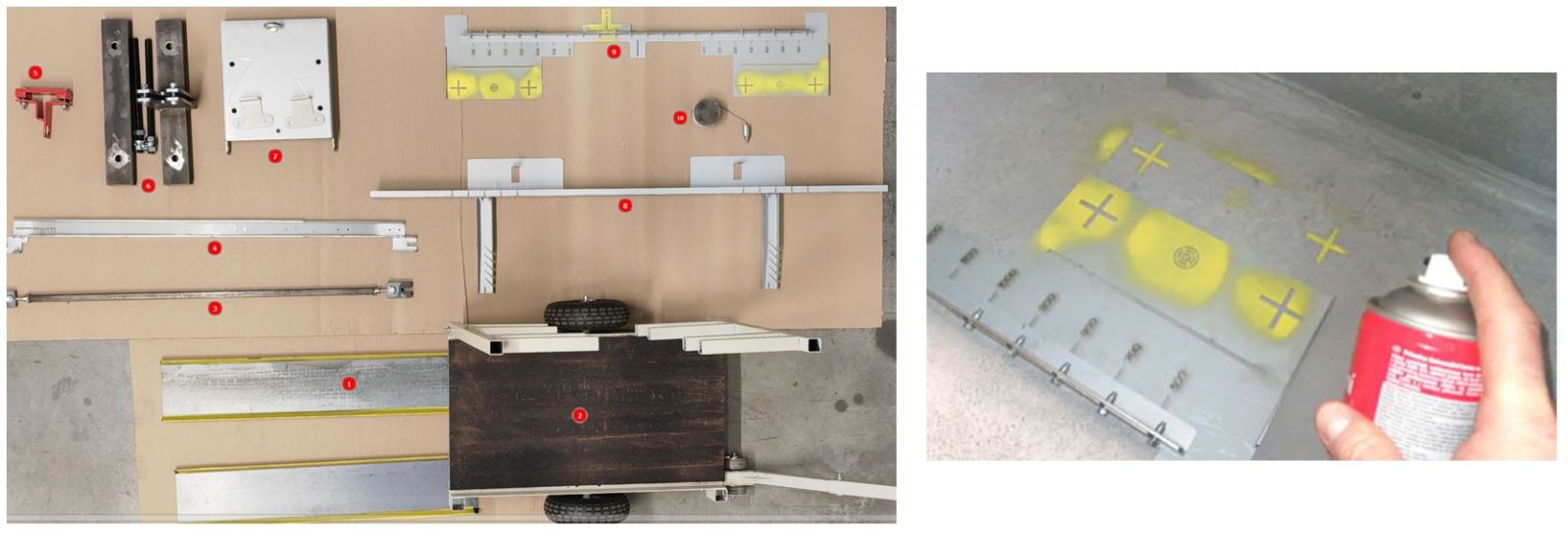

2, Installation without scaffolding – prepared for installation using Rigid or Tirak hoists

3, 80% of the installation can be carried out by a single installer

- Assembly jigs for easy installation and a precisely developed installation procedure.

- Reduced installation time – the connection of the control cabinet and shaft is designed according to the plug-and-play principle. Connector work has also been simplified.

- One type of controller for all solutions up to 650 kg – the cabinet with inverter is positioned closer to the machine, with components always placed in the same layout for easier orientation for installers.

- One frame type for all solutions up to 650 kg (previously six different frame types were used).

- Smaller and lighter machine – lower price, reduced dimensions and weight.

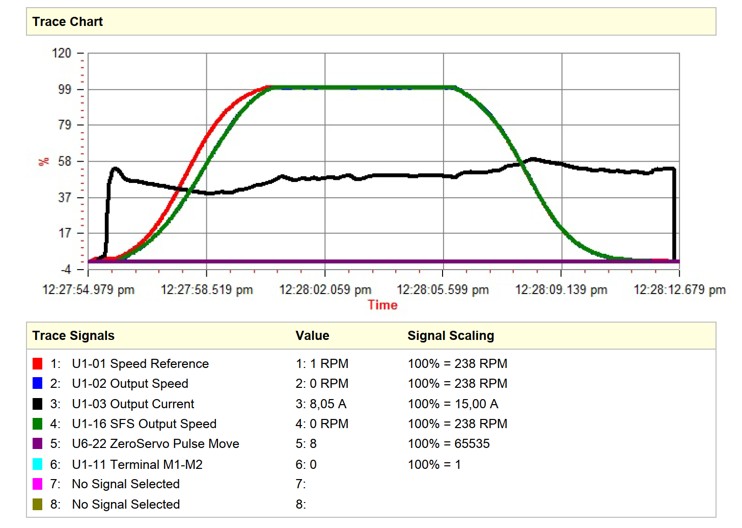

4, Best ride quality on the market thanks to absolute positioning system

- Limit switches, magnets, and buffers are no longer required – the system uses only a coded strip and a sensor.

- High stopping accuracy and reliability thanks to absolute position detection.

- New Yaskawa LA700 frequency inverter – ensures smooth starts and stops of the lift.

- No additional measures required for small head and pit.

- Door pre-opening – the lift begins opening the doors as the cabin approaches the landing.

- UMC – Unexpected Movement Control – prevents unintentional cabin movement.

6. Emergency automatic descent included in the lift price.

7. Minimized welding – only required for the floor and ceiling.

8. Load-bearing components (plastic-coated ropes) – improved ride performance and higher traction.

9. All lifts are monitored via the LC Monitoring 365 service.

-

All lift information in one place – easy access to complete lift data.

-

Constant control over the lift – always know what is happening in real time.

-

Faster problem resolution – remote management allows quick troubleshooting.

- More information about LIFT MONITORING