LC MAXI 1050

Lifts without machine room in limited spaces

|

Technical parameters LC maxi 1050

- Load capacity 1050 kg

- Number of persons 14

- Number of stations max 7

- Travel max 20m

- Cabin 1100x2100 mm

- Shaft 1650x2450 mm

- Shaft head 3350 mm (min. 2750 mm)

|

- Pit 1100 mm (min. 700 mm)

- Frame Type TLM10 maxi

- Gearless machine

- Engine power 7 kW / 19,5A

- Door 900mm wide

- Doors automatic 2 panel

- Rope 10x6,5mm

* In case of higher lift please contact our sales department for more information |

Lift Features

|

Design cabins

- Five series of lift cabs

- Dozens of lights, accessories and hundreds of color combinations

- Crystal clear surfaces, precise lines, perfectly manufactured

- Premium materials, stainless steel surfaces, LED lighting, design elements and sharpened glass

- The cabins are galvanized on both sides, which significantly increases their service life

<more information about design

.jpg)

|

Development and testing

- All elevator components going through exacting testing in the test tower to meet the high demands on safety, quality and reliability

- During testing, we are focused on permitted noise levels in protected areas

- We monitor lifts for your safety - the lift can be monitored from anywhere and anytime, some problems can be solved remotely

- "The development of elevators is very important. It is not enough to buy cheaply and assamble at the customer"

|

|

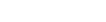

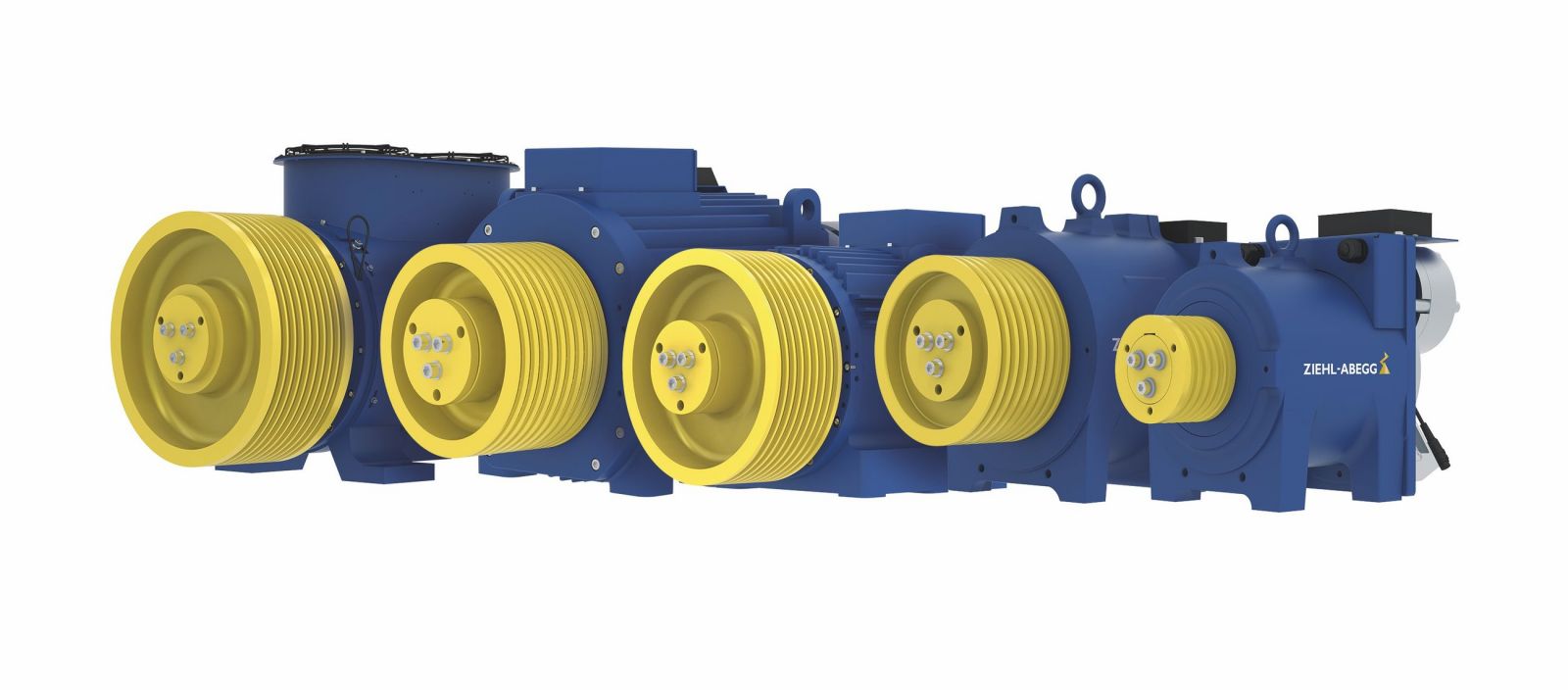

Hi-Tech components

- We produce elevators for you in our factory in Karviná

- We complement our own production with quality components of leading European manufacturers

- SICOR and Ziehl Abegg machines - our long-time partners, one of the largest and best machine manufacturers in Europe

- Klefer doors - part of the Tecnolama multinational group, delivered to 90 countries of the world <more about Klefer doors

- Steel ropes last up to 2x longer than belts

- Pushbuttons in the cabin and station

- Top lift control "VEGA"

|

Swiss production technology

- We use Hi-Tech machines from Switzerland (laser and Bystronic press brakes, Trumpf sheet metal punching from Germany) for production.

- Due to these technologies, LC lifts are made as compatible kits, which guarantee their long life

- Due to the technology of production and materials used, the whole structure is lightweight

- All components of the elevator going throught exact testing

- The main parts of the elevator (cab, frame, brackets and more) are galvanized

- "If the components are not galvanized, they often look like ten years old after one year of usage"

|

Energy-efficient lifts

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

(1).JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)